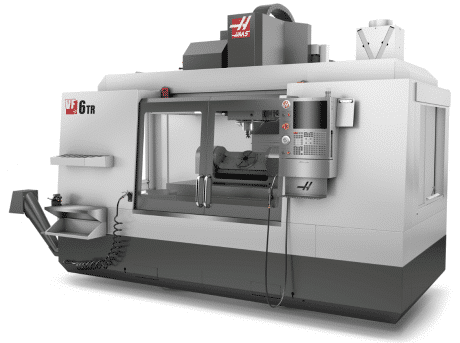

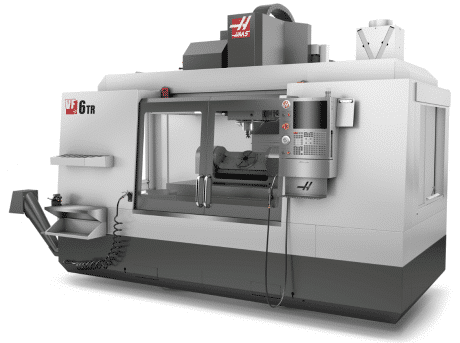

Haas Automation Machining Center

Machine tools play an important role in industrial production. With the advent of Industry 4.0 and the factory of the future, which is smarter, more efficient and cleaner, we are being forced to rethink our manufacturing processes.

New trends are emerging on the market. These include connected machining centers, green machining centers and hybrid machining centers.

Connected machining centers

With the rise of the Internet of Things and connected objects, machine tools are no exception. Machining centers are increasingly sophisticated and equipped with sensors (speed sensors, temperature sensors, etc.) that regularly transmit data. The data collected in this way can be used, for example, to predict possible machine breakdowns and carry out preventive maintenance.

Another important characteristic of connected machines is the possibility to control them remotely from a tablet or a cell phone and be alerted 24/7 in case of a problem so you can launch an intervention immediately. As a result, connected machining centers offer higher productivity and reduced downtime.

Green machining centers

In order to make manufacturing processes more environmentally friendly, several manufacturers have developed new machining centers with lower energy consumption and environmental impact.

The manufacturer BENZ, for example, has integrated energy recovery technology into its machines to operate its sensors. The speed of the tool, the vibrations and the heat generated by the machine are all elements that allow energy to be recovered and thus avoid the use of batteries, which are inevitably less environmentally friendly and often have to be replaced.

Hybrid machining centers

These machining centers combine turning and milling or milling and 3D printing in one machine. DMG MORI is a pioneer in this field with its Lasertec 65 3D which combines milling and additive manufacturing.

Hybrid machine tools can be more efficient by reducing production cycles. They also offer the possibility of creating parts with designs that would be impossible otherwise. Lastly, because of their combined functions they allow you to save space by having one machine instead of two.

There are some other selection criteria when choosing a machining center:

There are some other selection criteria when choosing a machining center: