Nozzles are available with different jet shapes.

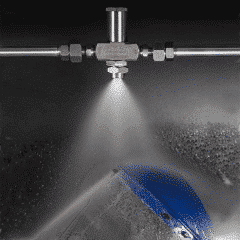

DELAVAN hollow-cone spray nozzle

Full-cone nozzles and hollow-cone nozzles

These provide a high-pressure jet made up of small droplets. The spray angle varies from 30° to 170° depending on the nozzle.

Full-cone vs hollow-cone:

- Full-cone nozzles spray larger droplets in a cone-shaped jet that covers the entire area of a circular shape.

- Hollow-cone nozzles spray smaller droplets around the jet’s edge to form a ring shape.

Full-cone nozzles

There are two possible types of flows for full-cone nozzles:

- Axial-flow full-cone nozzles evenly distribute the liquid over a circular surface.

- Tangential-flow full-cone nozzles rotate the liquid, ensuring even, regular distribution with stable pressure.

Disadvantages: Full-cone nozzles are not compatible with spray booms.

Hollow-cone nozzles

There are two possible types of flows for hollow-cone nozzles:

- Axial-flow hollow-cone nozzles are used for spraying extremely fine droplets.

- Eccentric-flow hollow-cone nozzles produce fine droplets and have very little risk of clogging.

Flat spray nozzles

Flat spray nozzles, or flat fan spray nozzles, are used in pneumatic atomizing nozzles.

Flat fan atomizing nozzles produce very small droplets with spray angles of up to 80°. They are best suited for misting.

Flat sprayers have a nozzle that divides the liquid into small droplets and distributes them in a flat, fan-shaped jet. The angle of the flat jets varies between 15° and 145° depending on the nozzle.

Solid-stream spray nozzles

This type of nozzle does not produce any droplets. The solid-stream jet is formed by forcing liquid through an orifice.

Straight jet nozzles

These nozzles project the jet in a straight line, which means that the spray angle is 0º. This type of nozzle is therefore best suited for applications that require a strong impact on a very precise point (power washing, paper cutting).

Multi-jet nozzles

These have several individual fine-spray nozzles that spray liquid over a very large area. They are particularly suitable for working with gaseous fluids, controlling dust, or cooling steam, as they produce a fine, full cone-shaped atomization that is very dense over large areas.