The check valve is a widely used device in hydraulic, pneumatic and ventilation systems. Its function is to allow the fluid to pass in only one direction. It is also called a non-return valve.

The check valve is a widely used device in hydraulic, pneumatic and ventilation systems. Its function is to allow the fluid to pass in only one direction. It is also called a non-return valve.

The check valve allows fluid to flow in one direction only, blocking its passage in the opposite direction. Fluid backflow can damage circuits, especially hydraulic circuits. These valves can also prevent liquid or steam leaks if there are faults in the pipe structure. They are also installed in sewage pipes to prevent backflow and the passage of bad smells.

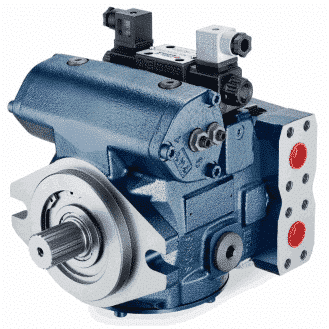

Check valves can be found in hydraulic pumps and motors, ventilation systems, pump pipes, hydraulic and pneumatic connections, heating systems, as well as in the evacuation systems of kitchen sinks, washbasins, bathtubs, toilets, washing machines, etc.

There are different types of check valves, the most common being swing, ball and disc valves.

Gate check valves

Ball check valves

Disc valves

They are suitable for pipes with a larger diameter, while ball valves are intended for smaller diameters. They can be used in hydraulic or pneumatic systems. It is often used in the pharmaceutical, chemical and petrochemical industries, etc.

There are several factors that will dictate the choice of a check valve. For example, the desired flow rate and speed will determine the size of the valve you need. This must be sufficient for the fluids to circulate easily, without the risk of clogging.

The type of fluid and the size of any solid particles must also be taken into account. In the case of waste water, you will need to opt for a gate valve with a diameter that allows fibrous substances to pass through.

The type of fluid also influences the choice of valve material. For applications with seawater or other types of salt water, you should opt for a valve with stainless steel components. Attention should also be paid to the choice of material for a check valve intended for corrosive fluids or for food use. For example, for acidic fluids, it is crucial to choose a polymeric material suitable for the type of acid in question, as the resistance of different polymers varies depending on the nature of the acid.

In the case of fluids for food use, stainless steel valves are generally used because they are easier to clean and meet hygiene standards.