Allied Machine & Engineering insert drill bit

Insert drill bits are used for drilling large diameter holes. They are usually found on machine tools. They can be used at a much higher speed than solid drill bits and on a wider variety of materials. They are more economical because you can replace the inserts when they become worn. Replacing an insert can be done very quickly. They also have several cutting surfaces per insert.

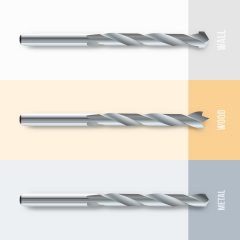

Solid drill bits have the advantage of being more rigid. They are suitable for small diameters and tight tolerances. If they become worn, they can easily be reset (sharpened).

I like how you mentioned that drill bits are designed for drilling metal and wood. My uncle mentioned to me last night that his friend is looking to find industrial drill bits for his upcoming project and asked if I have any idea what is the best option to do. Thanks to this informative article and I’ll be sure to tell him that he can consult a well-known industrial bolts supplier company in town as they can answer all his inquiries and will help them with their needs.