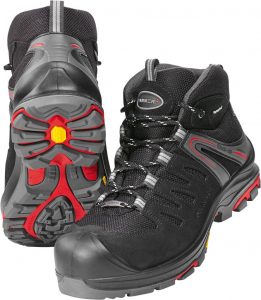

Example of Jalas anti-perforation safety shoes

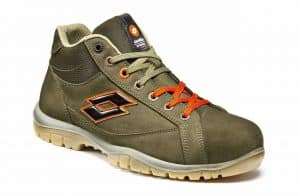

The safety shoes you choose will depend on the level of protection you need while taking into account comfort, aesthetics and price criteria.

All shoes that are EN ISO 20345:2011 compliant are equipped with an anti-crushing toe cap that resists an impact of 200 joules. Safety shoes must also be a minimum anti-slip on smooth and greasy floors in industrial environments and the soles must be hydrocarbon resistant. It may be necessary to check whether the soles are classified anti-perforation in particular for interventions in mechanical workshops, anti-static in particular for workshops likely to have electrostatic discharges, or fire-retardant, for example in welding workshops. The shoes must also show good wear resistance to avoid premature wear.

Once the necessary types of protection have been determined, one of the first criteria for choosing the most comfortable shoes possible is to determine whether the employees concerned can wear low shoes or whether they should wear high shoes. Then you can decide whether the shoes can be leather or fabric, or if they need to be made of polymeric materials to ensure waterproofness. The material chosen will often determine the weight of the shoes: the lighter the material, the more comfortable they will be. Another vital element to consider when it comes to the comfort of the shoes is the type of material used for the toe cap.

Generally, safety shoe sizes are a bit big, but you should avoid ordering smaller shoe sizes than usual as manufacturers anticipate that they will be worn with thick socks in order to improve the user’s comfort.

very good

It is a really good article to choose the shoes.

Very nice article. Actually, I was very confused as to how to choose the right safety boots but this article has helped me to learn everything that I need to know about choosing safety shoes. Thanks a lot for sharing. Keep it up.

Nice One Article Thanks For Sharing

I like the valuable information you provide in your articles. Thanks for sharing

This valuable piece of content is very helpful for me. Also many peoples seeking honest review about safety shoes and I think this information is best for them.

I was confused about how to choose safety boots this article has helped. Thanks a lot for sharing. Keep it up. I will love to read further article related to footwear.

Thanks in advance

Steel toe designed to withstand falling pressure from objects. They can prevent a wide range of foot injuries and provide comfort for long-hour standing on hard or rocky grounds