In order to choose the best temperature sensor for your needs, you should ask yourself the following questions:

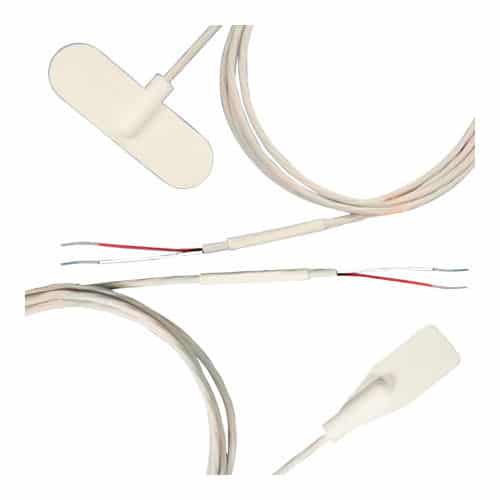

Should I choose a contact or infrared sensor? Contact sensors can come in different forms, there are sensors suitable for measuring the temperature of a surface, or sensors for measuring the temperatures inside the material. In any case, the quality of the contact between the sensor and what is to be measured is essential.

Infrared sensors can only measure the temperature of the surface they are aimed at. Even if they do not require contact, you must pay attention to the nature of the atmosphere between the sensor and its target, which can influence the measurement.

In the case of contact sensors, what technology should you use? There are several different options: thermocouples, resistance sensors, etc. It cannot be said that one technology is better than another, each has its advantages and disadvantages:

| Criteria |

Thermocouple |

RTD |

Thermistor |

| Precision |

* |

*** |

* |

| Linearity |

** |

*** |

* |

| Sensitivity |

* |

** |

*** |

| Cost |

*** |

* |

** |

The response time of the sensor may also be important to consider if temperature variations are to be measured, with thermocouples having a faster response time than RTDs.

The temperature range you need to measure is obviously important when choosing the sensor itself, as is its technology. Thermocouples and RTDs are classified according to the materials their sensitive element is made of and they have different measuring ranges.