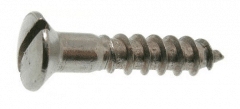

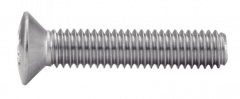

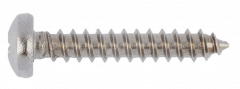

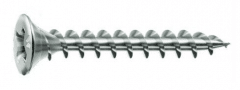

Fixing screws are mechanical elements that allow several parts to be fixed together. They make it possible to assemble parts that can then be easily dismantled. Many people confuse screws with bolts. They are both fastening and joining elements: a screw is a threaded rod while a bolt is the set formed by a screw and a nut.

It is important to distinguish between fixing screws and power screws (also known as lead screws), which are one of the components of a ball screw (mechanical transmission element) and which we will not discuss in this guide.