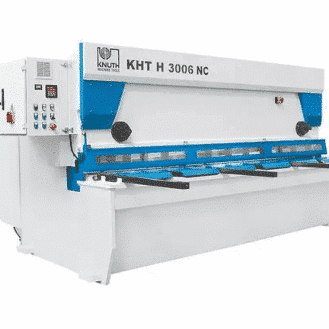

AEG jig saw

Jig saws are portable electric saws for cutting panels.

The cutting angle is determined by the inclination of the blade in relation to its base plate, which is placed on the panel. As the tilt is not very precise, it is better to limit yourself to cuts at 90° in relation to the tabletop with this type of saw.

Cutting capacity is defined by the height of the blade protruding from the base when in the “retracted” position. In general, you will not be able to cut a panel over 10 centimeters thick, especially as the quality and precision of the cut deteriorates with the thicknesses of the panel due to the flexibility of the blade.

Cutting with a jigsaw is coarse and it is better to choose another cutting method for finishing work, for example a circular saw for making straight cuts.

With a jigsaw, the movement of the blade is pendular, i.e. the blade moves back slightly as it rises, which limits heating and allows better chip evacuation. On some jig saws, it is possible to adjust or even disable this movement, especially when you want to cut fragile material.

The edge of the blade on the top of the panel can cause it to splinter. It is therefore preferable to position the panel with the side that will be visible opposite the saw and to choose the blade best suited to the material to be cut.

Jig saws are equipped with a variable speed drive which allows the speed to be adapted to the type of material: the harder the material, the more the speed must be reduced.