Numerous factors must be taken into consideration when choosing a circuit breaker.

First are the basic electrical characteristics of the equipment involved, such as the following:

- Whether it uses an AC or DC current.

- The voltage, whose determining factor is the highest voltage that can be applied across any two conductors in the circuit.

- The short circuit current level that will trigger the device to protect it.

Other factors include the type of environment in which the equipment will operate, including the ambient temperature. This will impact the type of box or protection needed to protect your circuit breaker from factors such as humidity, temperature, and dust.

There are multiple types of circuit breakers and one of the main differentiators is the dielectric material – or non-material in the case of a vacuum – they will utilize to quench any electric discharges they encounter. These can include air, a vacuum, oil, or the gas sulfur hexafluoride SF6. Each is suited for particular applications:

- Air for low-voltage applications

- Vacuum for higher voltages

- Oil for medium to high voltages

- SF6, which is the most versatile and widely used for most medium to high-voltage applications because of its

- high dielectric strength

- thermal stability and conductivity

- high density (some five times that of air)

- inertness

- non-toxicity

- ability to recombine very rapidly after the source of sparking ceases

Steps to selecting a circuit breaker include determining the load type. The key factor is whether the load will be static or dynamic:

- If the load is static, it will never draw more than the rated current even when at full power.

- If the load is dynamic, the device may draw a higher current than rated when starting.

Devices in the former category might typically be heaters and in the latter motors or transformers.

Given the extreme danger that may result from the use of faulty or otherwise inadequate devices, another important consideration in circuit breaker selection is to ensure that they are genuinely manufactured by reputable suppliers and are not counterfeits. Visual clues that signify a device is non-compliant in this respect might include poor surface finishes such as imperfections in the outer casing, corrosion of metal parts, and illegible markings. In Europe, all compliant devices must without fail carry a CE mark. Other factors to consider might also include the product’s weight (ensure consistency with previously purchased compliant products), and the provision of a Type Test certificate from a recognized laboratory or authority to prove compliance.

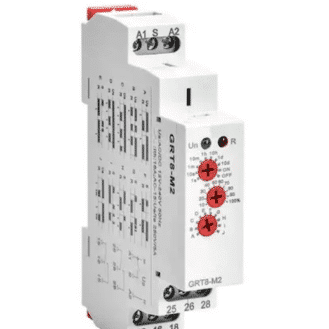

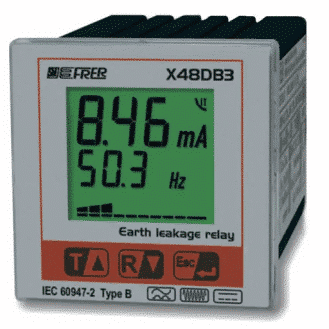

In terms of their physical construction, there are several types of circuit breakers including differential, thermal, and electronic devices. Each has its own performance characteristics and suitable area of application (see the following sections for more detailed information).